How to Overhaul an Electric Motor

There are several things to consider when undertaking an Electric Motor Overhaul. These procedures include examining the bearings, insulation resistance, and stator winding. The electrical resistance of an electric motor can be checked by switching in a multimeter probe. It is also important to mark the connection and motor housing for a smooth boxing back procedure. Preventing the motor’s rotation is also important before stopping it for overhaul.

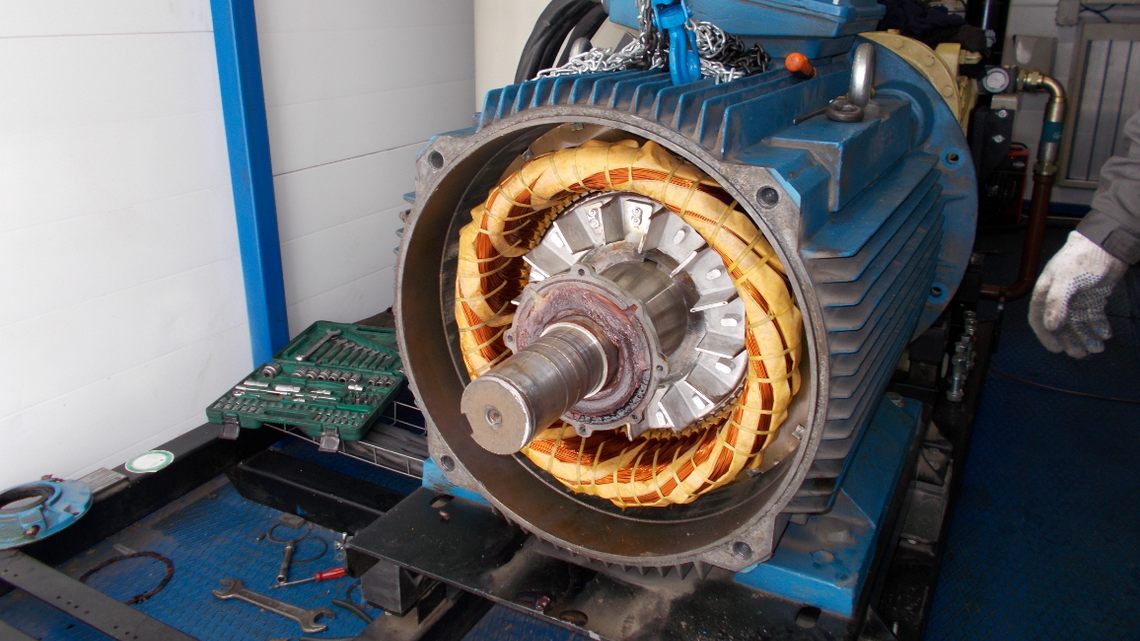

Dismantling an Electric Motor

There are several steps to overhaul electric motor. The first step is to determine whether the engine has a short winding. A short will cause the motor to trip a circuit breaker or blow a fuse. A short can also occur between the motor’s terminal and the ground. This short will likely occur through the steel casing. If the motor does not have a short, the next step is to check the rotation of the motor. It is probably not a serious problem if the motor is still turning.

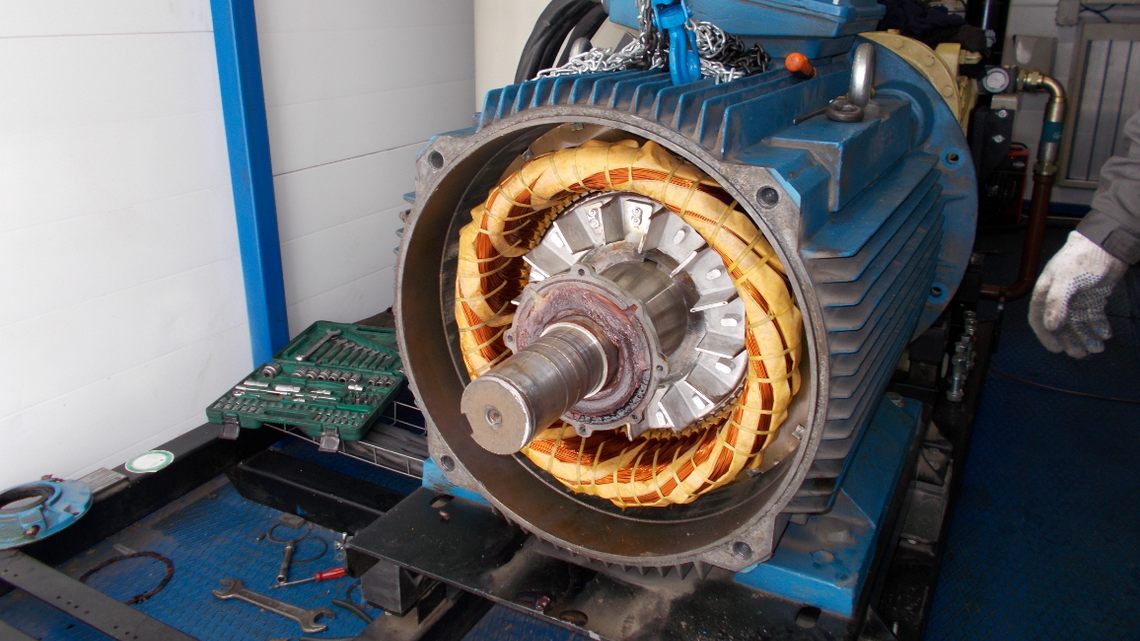

Examination of the Stator Windings

Any electric motor overhaul must include a stator winding examination. An electric motor’s windings must be checked for insulation and mechanical wear. To accomplish this, attach the probe to the earth using a multimeter. To check the running amps of the motor, you can also use a resistance meter. Compare the values to the FLA listed on the motor nameplate. Additionally, the motor’s look might provide information about its state.

Examination of the Bearings

An essential component of an electric motor overhaul is bearing inspection. An inspection improves the machine’s overall performance by providing crucial information about the bearing’s state. It’s crucial to adhere to the AEGIS(r) Handbook and use the appropriate safety gear when examining the bearings.

Evaluating the Resistivity of the Insulation

Electrical motor insulation resistance is crucial, especially when an engine has been idle for more than two months. The windings may have gotten wet during this period, which would have reduced the insulating resistance. An extensive inspection is necessary in these situations.

Detection of Short Circuits

To prevent short circuits, electric motor testing must be done correctly. Disconnecting the power source is the first step in the procedure. The motor is then examined with the help of the motor control cabinet. The sequencing of these tests should be predetermined.

Replacement of a Failing Motor

There are many factors to consider before replacing an electric motor. First of all, the design of the engine is important. This determines its efficiency and suitability for the application. Another factor is whether a motor shop can fabricate a new motor that fits the same space and power requirements as the old one. While some motors can be repaired, others may have done all their work. In such cases, replacement is the more economical option. You can reach out to https://www.ghaimagroup.com/ and get an expert.

Basketball fan, Shiba Inu lover, DJ, writer and designer of various specialties. We work at the intersection of simplicity and informatics to save the world from bad design. Sometimes I do random things with friends. I am developing my own business.